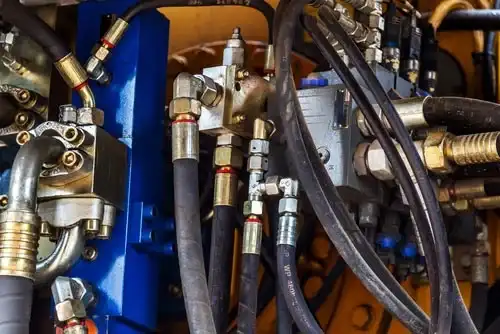

24 hour on-site hydraulic repair, replacement, hose & fitting services.

24 hour on-site hydraulic repair, replacement, hose & fitting services. 24 hour on-site hydraulic repair, replacement, hose & fitting services.

24 hour on-site hydraulic repair, replacement, hose & fitting services.

Sapphire Hydraulics is the authority on hydraulic hoses, bringing our customers a complete selection of products from top name brand manufacturers, as well as custom-made hoses. We serve commercial and industrial customers throughout Houston and nearby areas; plus, we’re the go-to choice among hydraulic hose suppliers in the region.

We invite you to call or email us today for a quote on hydraulic hoses, and we’ll be glad to provide it. Whatever the brand, specifications or length, we’ll bring it to you at an affordable cost. As hydraulic experts, you can rest assured you’re getting top-notch service from someone who understands the products we’re selling. We stock and can order all varieties of hose.

Whether for a single application or in-bulk, Sapphire Hydraulics is prepared to be your go-to supplier for hydraulic hose supply in Houston. Not only do we have intimate familiarity with fluid power applications and major manufacturer specifications, we also understand the vital factors in choosing the right hose for every application.

Looking to buy from a trusted hydraulic hose supplier in Houston? You don’t have to look far! We’re a hometown choice and hydraulic expert, ready to provide you with a free quote on the products you need. Call today or email us with the products you need, part numbers, quantities or any other information you have, and we’ll put together a custom quote for you. We make it easy to buy today!

Call or email Sapphire Hydraulics today to inquire about hydraulic hose and cylinder repairs you need for your application. We stock trusted OEM hoses and can order from reputable manufacturers to ensure you have the right hydraulic hose for your specific fluid power system. Reach us at (713) 331-1131 or through the contact form on our website. Shipping available world-wide!

The key capability of hydraulic hoses, and the feature which differentiates them from other types of hoses, is the fact that they are capable of withstanding greater temperatures and higher levels of pressure than ordinary hoses. This can be extremely important in many industries, and that is the reason hydraulics are used in so many business areas. Knowing which hoses to use for a given application will therefore often depend on the kind of operational conditions they get exposed to.

Hoses with single-wire braiding are constructed with oil-resistant synthetic rubber lining, reinforcement of single-wire braiding, and resistance to fuel, oil, and abrasion.

When higher pressures are involved, it might be necessary to graduate to double-wire braiding, which can tolerate higher temperatures than single-wire braided hoses, and greater extremes of pressure. Its construction is like that of the single-wire hoses, other than the fact that it has double-wire reinforcement. It also has a synthetic rubber cover which is weather-resistant, allowing it to be left outside if necessary.

Double-wire braided hoses may be the most popular of all kinds of hydraulic hose. However, for applications calling for extreme high pressure or temperature, you might need to use 4-wire braided hoses, which are known as Multiple Spiral, and these feature four individual layers of braiding, being wound in alternating directions for strength and stability.

[gravityform id=”1″ title=”true” description=”false” ajax=”true”]

These hoses are typically utilized when some type of return line is needed, such as return hoses, lube lines, or air lines without a brake application. They are also used for petroleum and water-based hydraulic fluids in vacuum applications when tight routing is needed for proper function. The tube is typically black, oil resistant, and reinforced with a pile of woven or braided textile fiber and a spiral of body steel wire, then covered with an oil and weather resistant synthetic rubber. These hoses can function in a range of -40 degrees Fahrenheit to 212 degrees Fahrenheit, and the pressure will typically max out a total of 600 psi.

Spiral wire hoses will typically consist of three parts: a seamless oil-resistant rubber tube, a spiral of high-tensile steel wire, and then a synthetic rubber housing that is oil, abrasion, and weather resistant. These hoses are typically very flexible, and are used across modern construction, forestry, mining, and marine equipment. These hoses have an operation range of -40 degrees Fahrenheit to 250 degrees Fahrenheit, and up to pressures of 13,000 psi.

This type of thin hose makes use of a thermoplastic inner tube that is resistant to hydraulic fluids which is reinforced with a synthetic fiber, and then covered in a thermoplastic material which is resistant to weather conditions and hydraulic fluid. These hoses are commonly used in construction equipment and hydraulic lift equipment, in lubrication lines, pressure gauges. These hoses can typically operate in a temperature range of -40 degrees Fahrenheit to 199 degrees Fahrenheit, and up to internal pressures of 6000 psi.

These hoses have an internal hose of high-quality synthetic rubber compounds that are reinforced with a braided, high-tensile steel wire, and then covered with a synthetic rubber that is abrasion and weather resistant. The temperature range that these can operate is -40 degrees Fahrenheit to 212 degrees Fahrenheit and will often operate at internal pressures up to 8000 psi. These operating ranges allow them to be used in equipment that is used for logging, agricultural, road-construction, and the mining, oil, and gas industries.

From the cranes, vehicles, and machinery moving steel and other manufactured elements in a facility, to the machines stamping, pressing, and cutting the material being produced, all rely upon hydraulic systems to create the pressure and force necessary to work with these materials. Our technicians can repair the cylinders, hoses, and replace the fluid so that your machinery continues operating as it should.

The transportation industry makes extensive use of hydraulic systems, from tractor trailers hauling large machinery, to the cranes and forklifts that load and unload each shipment. Sapphire Hydraulics is prepared to repair the hydraulic cylinders on the pieces of machinery that are utilized in this industry.

Heavy equipment is a vital part of many industries in this country today, and it has helped to boost production while also reducing overhead costs. It can reduce the reliance on manual labor, and minimize any risks associated with human workers. Heavy equipment has become an absolute necessity in such industries as farming, forestry, material handling, manufacturing, transportation, and construction.

There are many more industries than these which also require the use of heavy equipment. Because usage is so widespread and so frequent, breakdowns are inevitable, and that is when you need a reliable and reputable company to service your equipment and minimize any downtime. That is the time to contact Sapphire Hydraulics.

Across several industries, from farming equipment to mining equipment and all the pieces of heavy equipment used in construction industries, these pieces of equipment rely heavily upon their hydraulic systems to properly function. Each of these needs not only the hydraulic cylinders to be in complete working order, but also the hydraulic hoses that attach to the cylinder, and the fittings for these hoses.

Our technicians are prepared to repair or replace your cylinders, hoses, the hose fittings, and any other aspect of the hydraulic cylinder.

Nothing is more frustrating than having a hydraulic system break down on you when you are trying to maintain a schedule and meet a deadline. A single worn-out or malfunctioning hydraulic hose can cause your entire system to be non-operational. When this happens, your best bet will be to contact Sapphire Hydraulics so we can supply you with the appropriate hydraulic hoses and fittings right at your worksite.

Similarly, failure of your hydraulic cylinder can also bring your whole operation to a standstill. Contact Sapphire Hydraulics so we can send a highly qualified and knowledgeable repair person to your site, so that your cylinder can be repaired or rebuilt as soon as possible.

Whenever you have a non-standard piece of equipment that you are working with, it could call for hydraulics which are custom-engineered and manufactured. We have had many years of experience in designing and building customized hydraulic equipment for our clients, and we can do the same for you quickly and affordably.