24 hour on-site hydraulic repair, replacement, hose & fitting services.

24 hour on-site hydraulic repair, replacement, hose & fitting services.

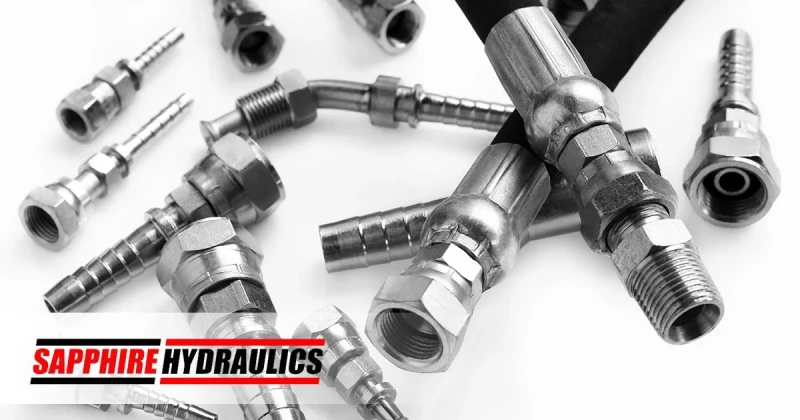

Figuring Out Which Connector Type You Need

It shouldn't be difficult to figure out the type of fitting you need when making connections on your project. There are a number of different connectors available for almost every need, so you'll certainly be able to find the appropriate connector to do the job. The first type of connector is the simplest, and that's just a cap which terminates the line right there.

Figuring Out Which Connector Type You Need

It shouldn't be difficult to figure out the type of fitting you need when making connections on your project. There are a number of different connectors available for almost every need, so you'll certainly be able to find the appropriate connector to do the job. The first type of connector is the simplest, and that's just a cap which terminates the line right there.