October 12, 2020

5 Reasons Hydraulic Pumps Fail

5 Reasons Hydraulic Pumps Fail

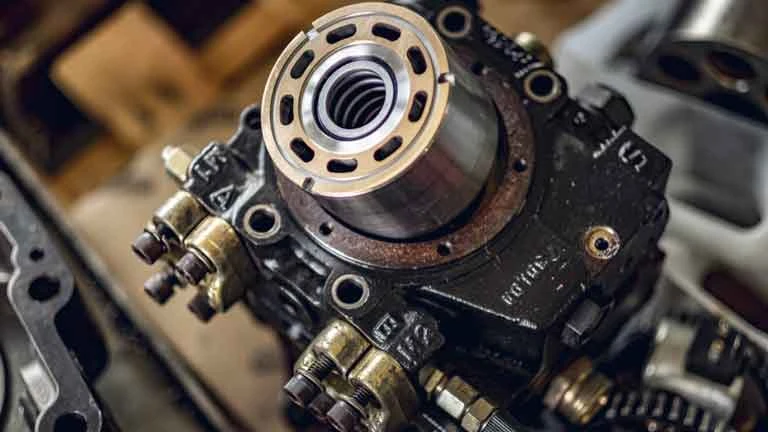

Hydraulic pumps are responsible for keeping a hydraulic system humming. Despite how long they’ve been around, these pumps still stand out as complex forms of machinery.

Their job is to turn the mechanical energy fed to them into hydraulic energy, but how they go about doing that is quite astounding.

Schedule Service

How Hydraulic Pumps Work

Hydraulic pumps must produce enough flow to overwhelm the pressure coming from the load.

As it works, the hydraulic pump will create a vacuum that aids in the movement of the liquid. The vacuum helps move the liquid from the pump reservoir to the inlet line. The continued movement of the pump will also result in the liquid going to the pump outlet and eventually, the hydraulic system.

Hydraulic pumps are typically broken up into 3 categories, those being Piston, Gear, and Vane.

Piston

These pumps are best suited for handling large flows at high system pressure. They are often used in

construction equipment, marine uses, offshore equipment and drilling, as well as a variety of industrial uses.

Gear

These pumps have relatively few parts overall, and operate at pressures of around 210 bar, and can often work at speeds around 3000-6000 rpm.

Vane

These pumps operate with a lower flow pulsation, and typically require a constant flow of the internal hydraulic fluid. Due to these conditions, vane pumps will often produce less noise, while maintaining high speed.

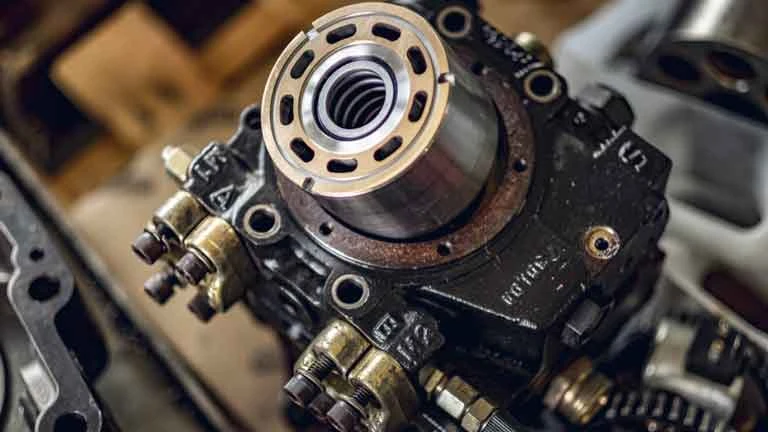

5 Common Causes of Hydraulic Pump Failure

The many components of a hydraulic pump need to be working in unison for the entire machine to work correctly. Given the components involved, it’s not difficult to imagine how things may start to go wrong.

Included below are some of the most common reasons why hydraulic pumps fail to function properly.

- Water Contamination

Water mixing in with the hydraulic fluid is bad news for the hydraulic pump. When too much water is present in the hydraulic fluid, the internal components may start to corrode.In addition to its corrosion-causing qualities, water is also problematic because it could freeze inside the pump.

- Hydraulic Fluid Issues

The hydraulic fluid present inside the pump can also be problematic even if it doesn’t mix with water.If some small particles fall into the liquid, it’s possible that they could deal damage to the inside of the pump. You must also check if the fluid level is correct or else that could alter the performance of the pump.Lastly, the viscosity of the hydraulic fluid must be just right to keep the pump from sustaining damage. Make it a habit to routinely check the viscosity of the hydraulic pump to see that it has not degraded just yet.

- High Levels of Heat

Heat can act as a kind of amplifier of other hydraulic pump-related issues. The heat itself can be a byproduct of other issues affecting the hydraulic pump so be sure to take note of it.

- Leaks in the Joints and Shafts

Because hydraulic pumps need the right pressure levels to function, anything that affects it can be disruptive or even damaging. Some of the joints and shafts of hydraulic pumps may spring leaks as they age causing holes to open up. If too much air gets inside the pump via the holes, it may not work as intended.

- Cavitation

Cavitation refers to the formation of small vapor-filled bubbles in areas within the pump where the pressure is low. Once those bubbles are exposed to high pressure, they may burst and start to damage the pump.

How Sapphire Hydraulics Can Help

Different kinds of issues can plague a hydraulic pump. Address them properly by getting in touch with the professionals. We at Sapphire Hydraulics are always ready to address your concerns so please feel free to reach out to us.ler.

Get in Touch

24 hour on-site hydraulic repair, replacement, hose & fitting services.

24 hour on-site hydraulic repair, replacement, hose & fitting services.