February 4, 2020

Hydraulic Hose Fittings & Connector Sizes Charts

Hydraulic hose fittings are very useful when it becomes necessary to connect various conductors such as tubes, pipes, and hoses

in a hydraulic system. Most of these connections will have a male and female component to accommodate the connection and will assist with the process of containing and directing the flow of fluid; while also preventing any leakages and maintaining pressure in the lines. Various types of fitting allow the designer to change the flow of the fluid, to split the flow of the fluid, or to elevate the lines. Below we've compiled a

hydraulic hose fittings chart describing some of the more common fitting sizes and types currently in use by pipefitters and other professionals.

Download Charts

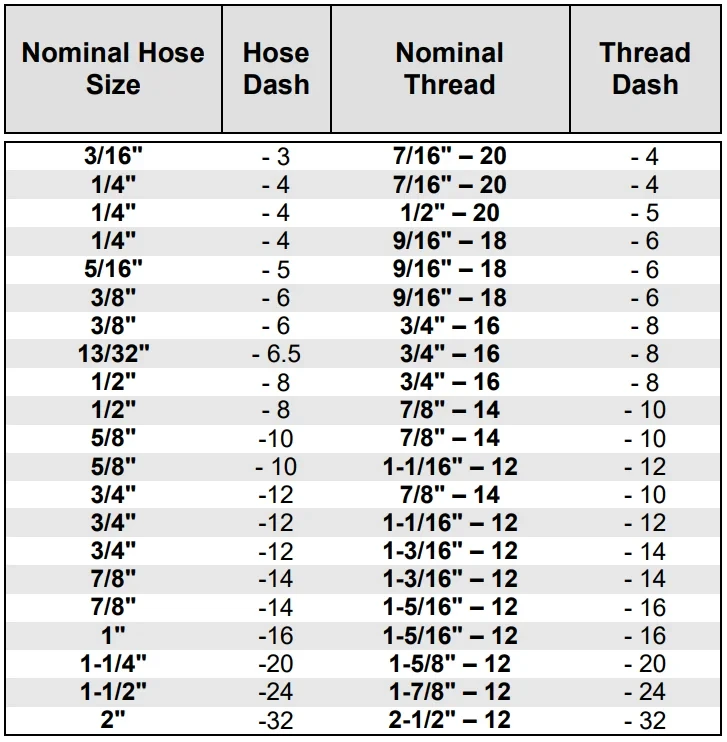

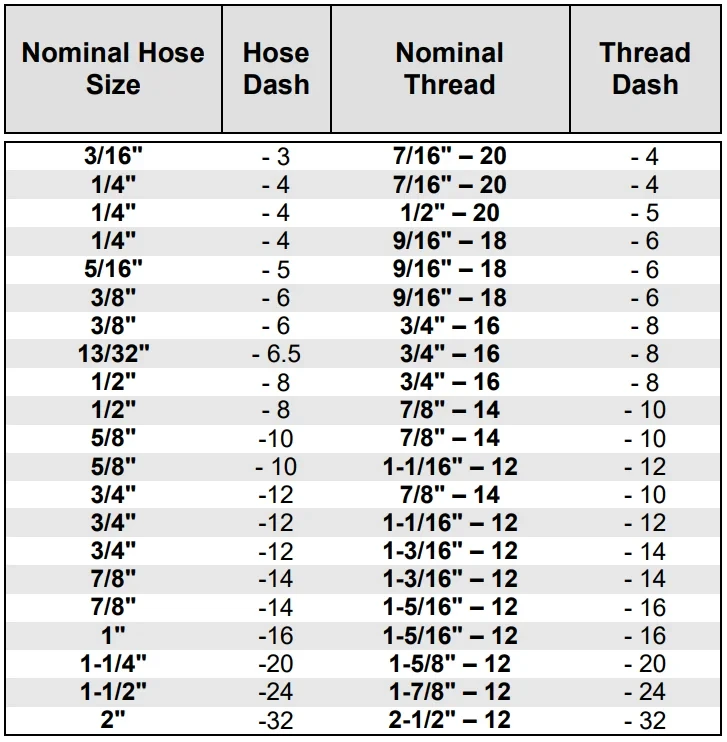

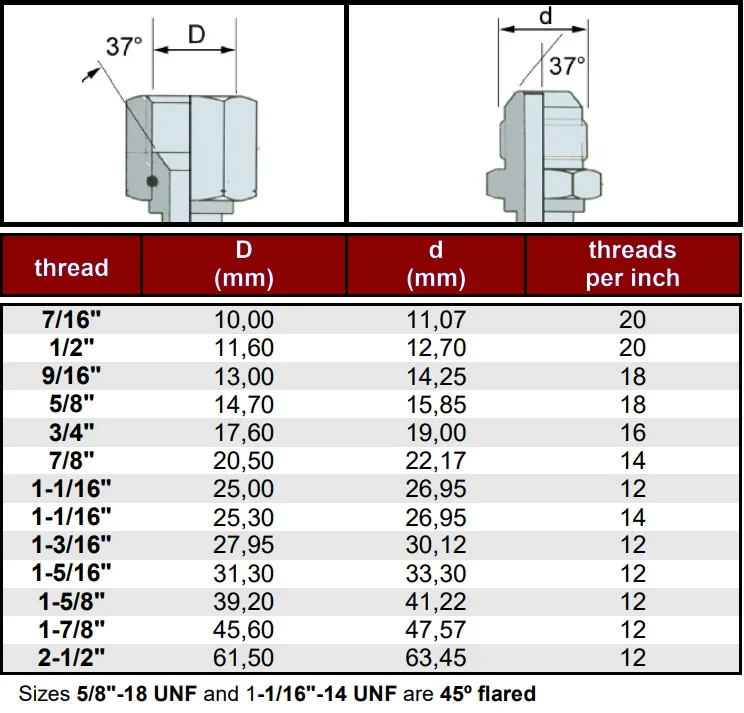

Thread Dash for JIC (37° Flared)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

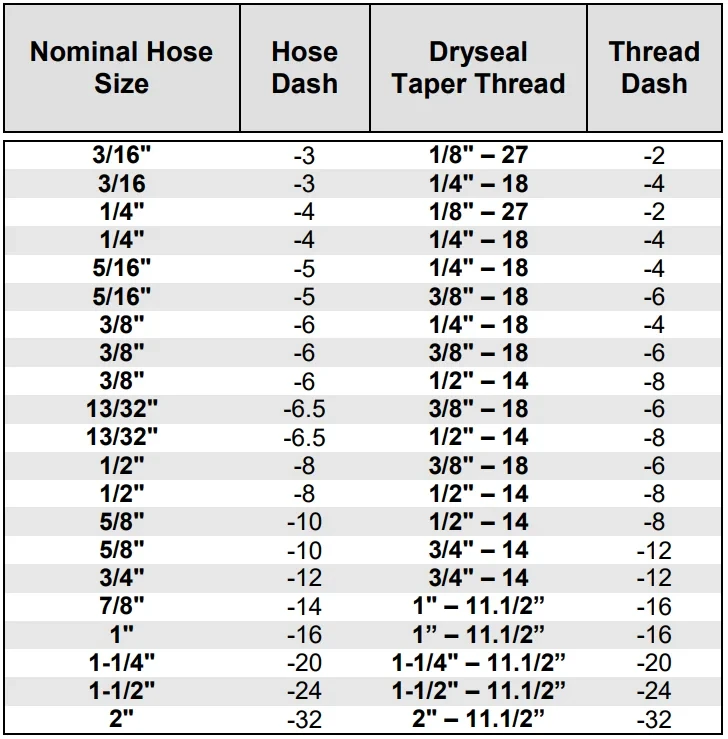

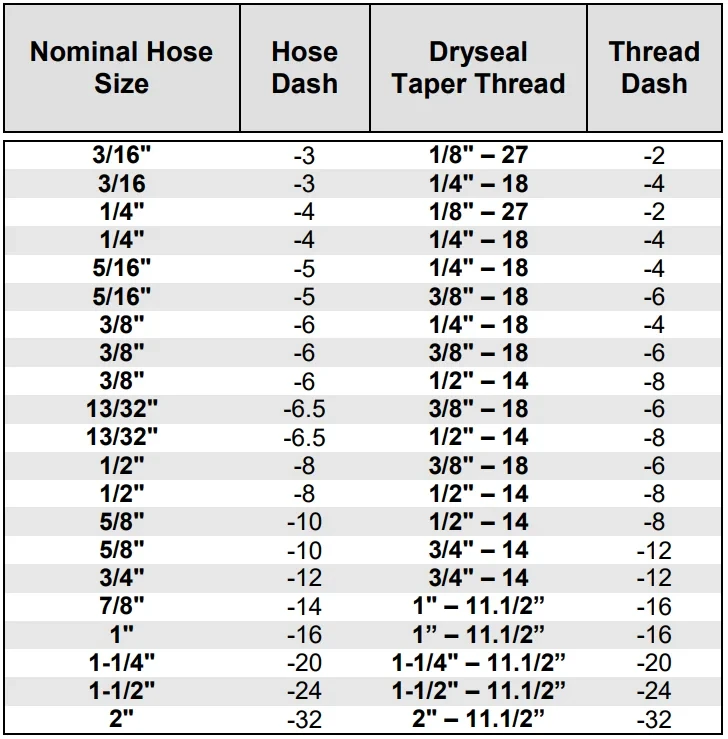

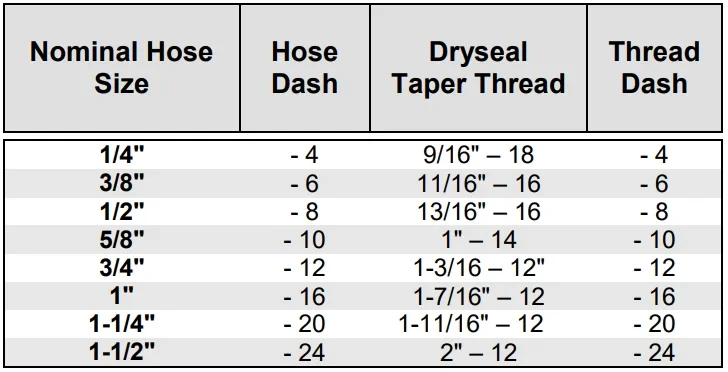

Thread Dash for NPT (Dryseal Taper)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

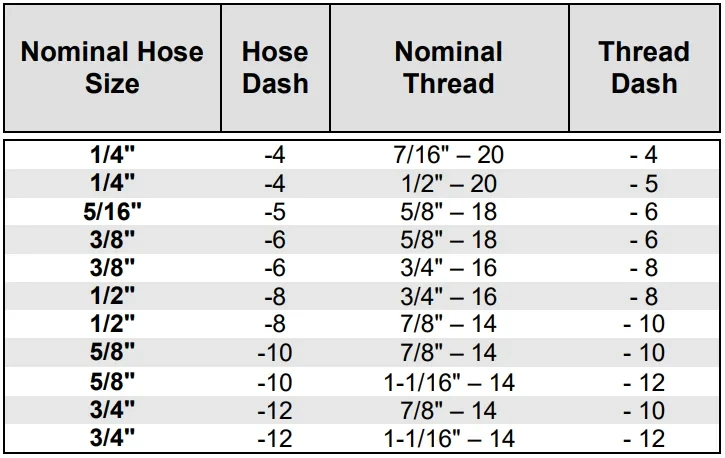

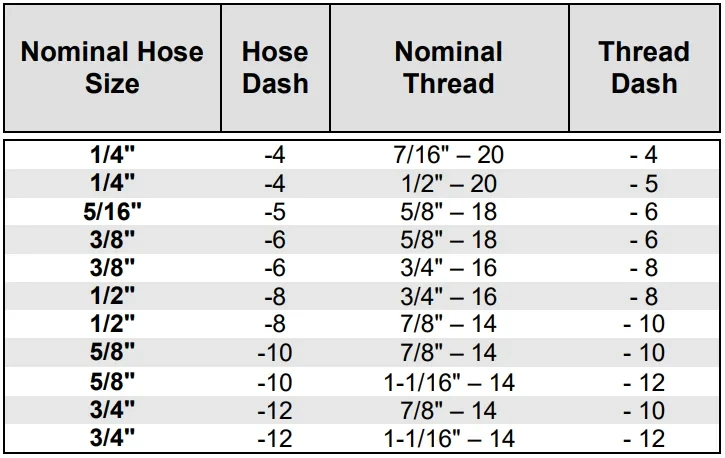

Thread Dash for SAE (45° Flared)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

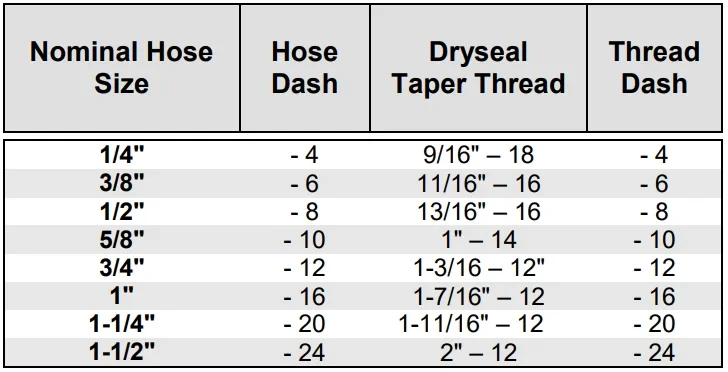

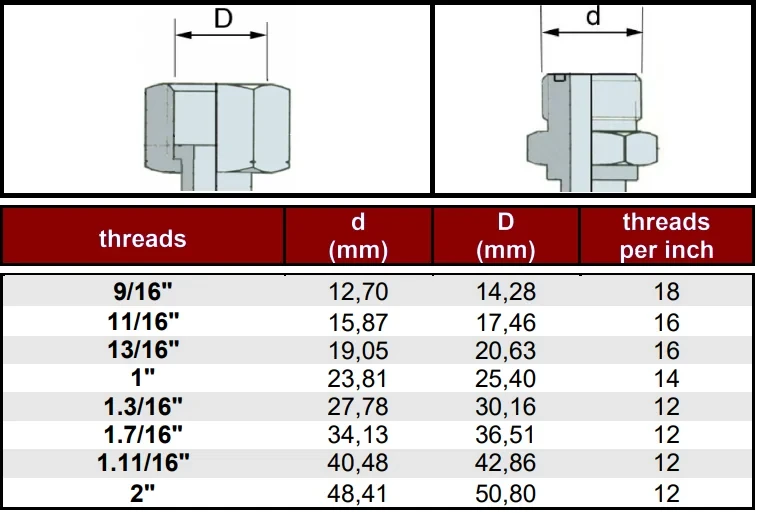

Thread Dash for ORFS (O-Ring Face Seal)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

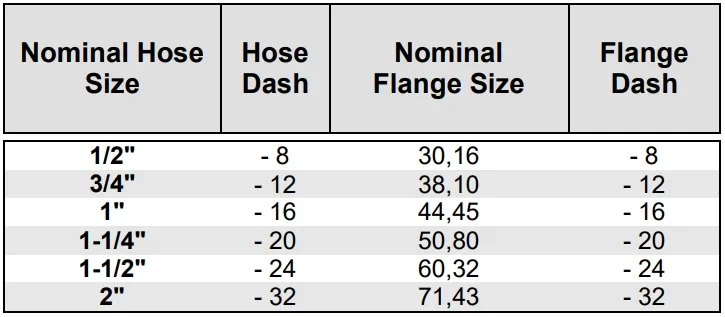

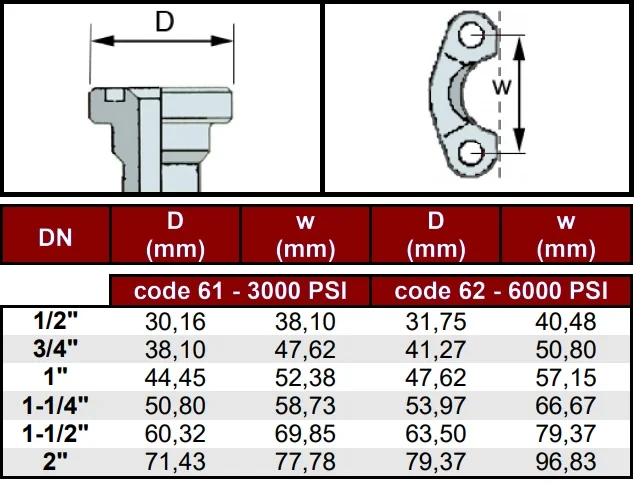

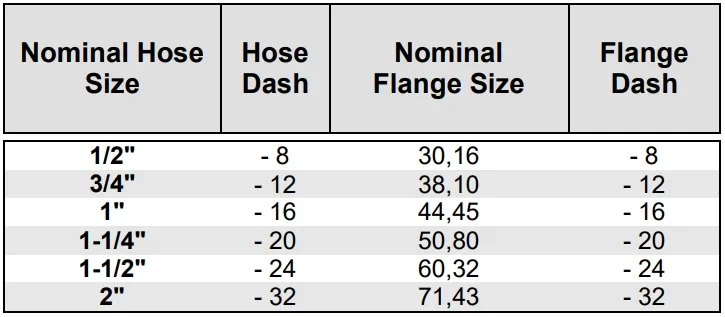

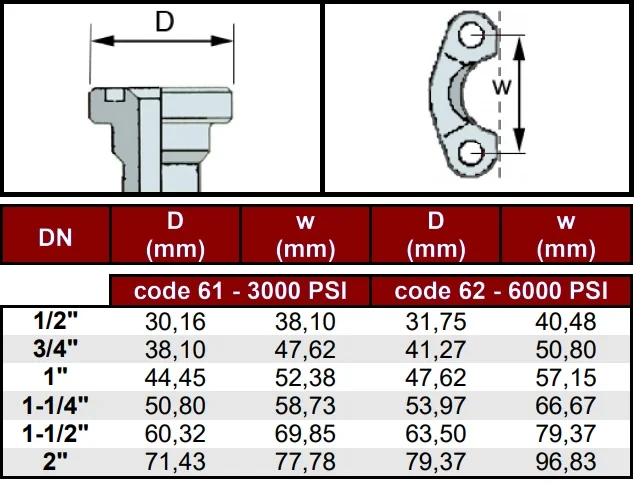

Dash Size for Code 61

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

Dash Size for Code 62

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

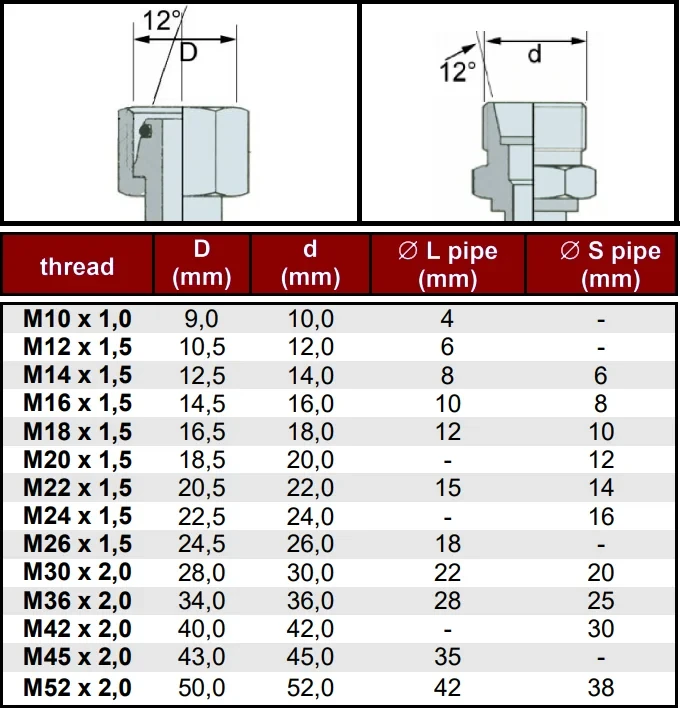

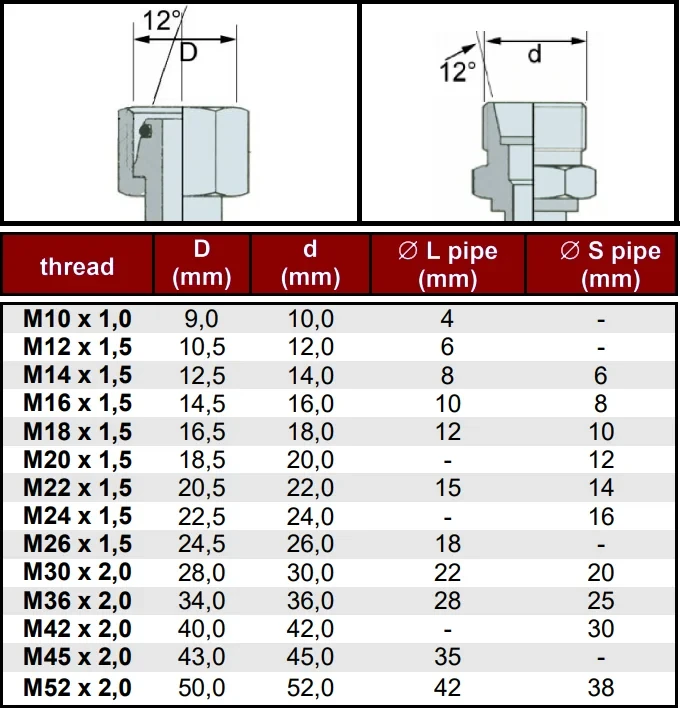

Metric Connections (ISO 8434-1)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

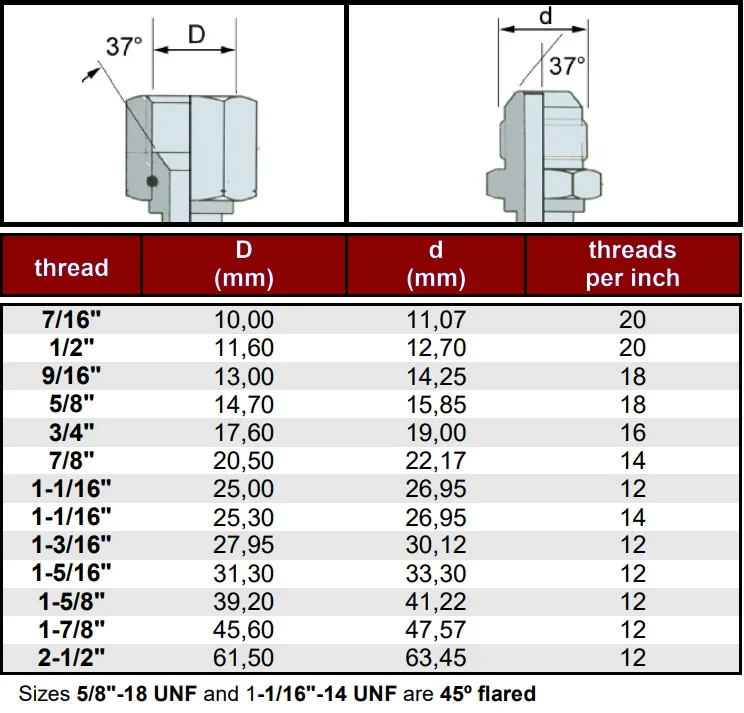

JIC Connections (ISO 8434-2)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

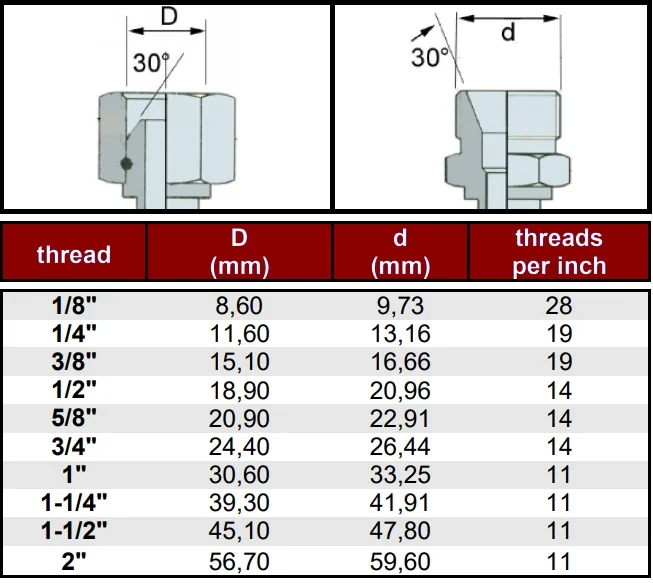

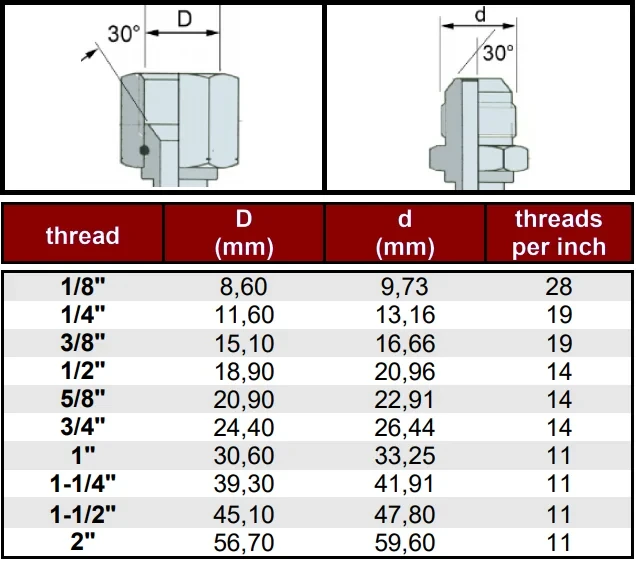

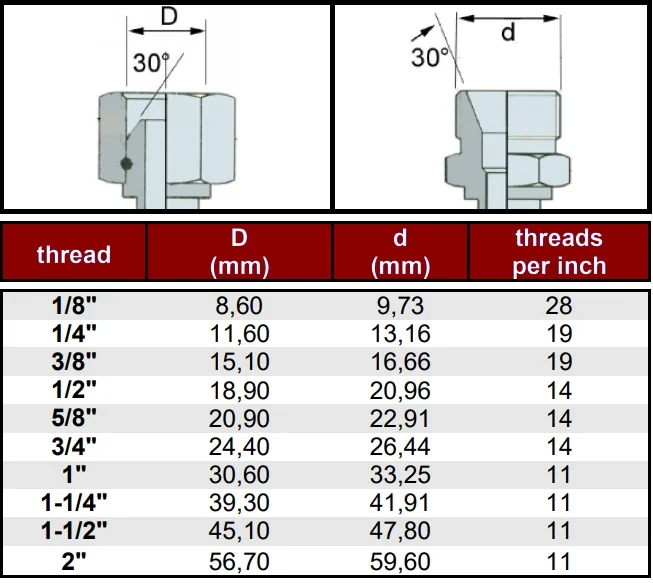

BSP Connections (BS 5200)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

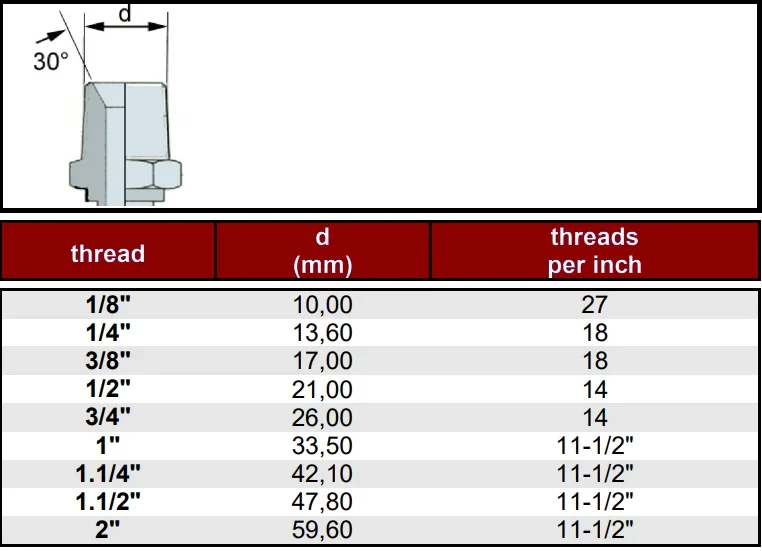

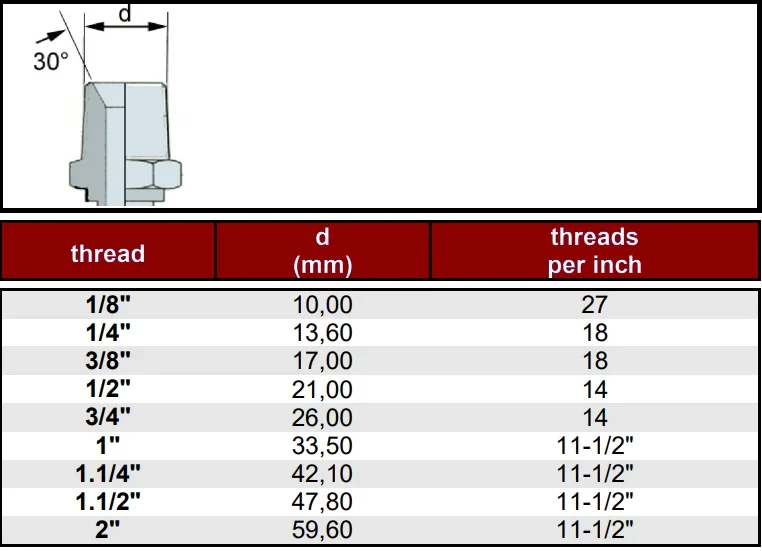

NPT Connections (SAE J476)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

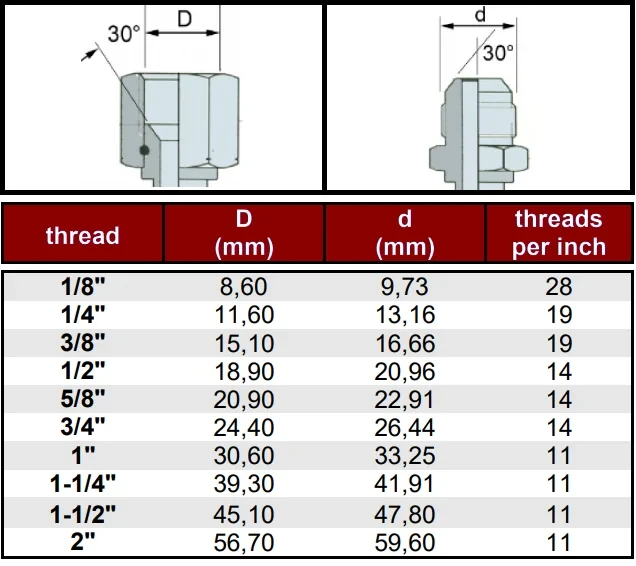

Japanese Metric Connections

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

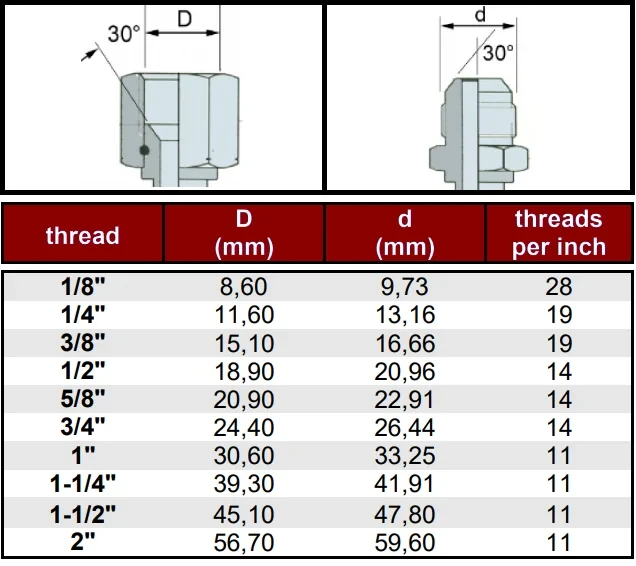

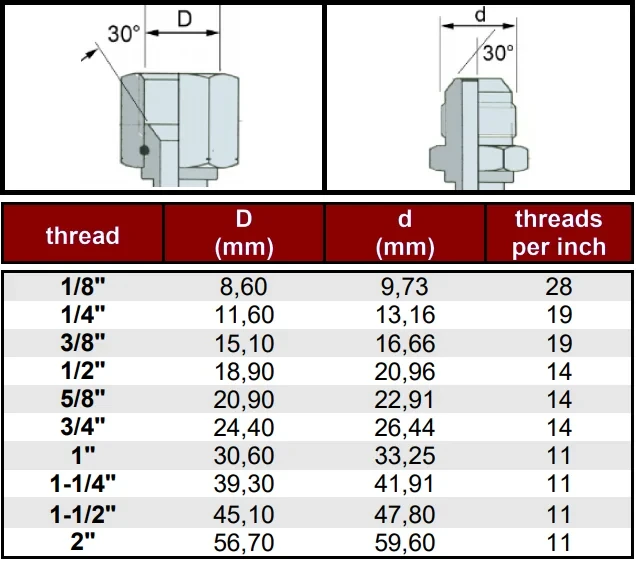

Japanese Gas Connections

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

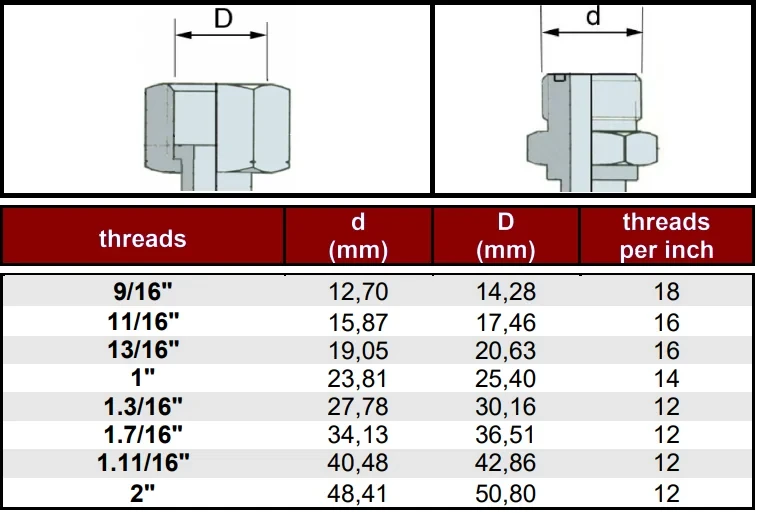

ORFS Connections (ISO 8434-3)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

Split Flanges (SAE J518)

Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors

Flare Fittings

Flare fittings are a kind of compression fitting which is generally used with some kind of metal tubing, often comprised of aluminum, copper, or soft steel, although other metals are sometimes used as well. Once assembly begins, a flare fitting is generally needed to secure the tapered end of flared tubing to the fitting, which is also tapered. This results in a leak-tight seal that can stand up to high levels of pressure. Flare adapters provide significant long-term reliability, making them suitable for most mission-critical situations, as well as for usage in locations that can be relatively inaccessible.

NPT Dryseal Taper

American National Standard Pipe Thread, often called national pipe thread standards, or NPTs, are technical standards adopted in the United States for the specific screw threads which are in general usage for pipes and threaded pipes. These standards include straight thread series as well as tapered series for a wide variety of applications requiring pressure-tight sealing or rigidity and, sometimes, both together. Threaded pipes offer an effective seal on pipes that are used to transport hydraulic fluid, steam, gases, or liquids.

The taper which is applied to NPT threads helps them to form a tight seal, because the flanks of the threads will become compressed against each other, rather than the straight thread connections or compression connections. The difference is that parallel or straight connections provide no seal at all and are merely tasked with holding the two pieces together. Pipe threads are designed to be used with or without accompanying thread sealants, depending on the particular application that they're being used for.

O-Ring Face Seal (ORFS)

As you might guess from the name, an

O-Ring Face Seal fitting makes use of an O-ring right at the face of the fitting to eliminate leaks in systems that make use of high-pressure hydraulics. ORFS connections utilize O-rings that are typically seated in the face groove of the fitting, and these elastomeric seals provide a leak-proof flared tube fitting which should eliminate hydraulic leaks when properly implemented.

As the connection is tightened, the O-ring will compress against a flat face sleeve, and this creates a metal-to-metal seal, with the O-ring providing a leak barrier. O-ring face seal connections are capable of eliminating hydraulic system leaks up to pressures reaching 6,000 psi. Another thing that makes them very popular is that ORFS connectors can easily be assembled or disassembled out in the field when it's necessary to replace O-rings or even replace the entire assembly.

JIC Fittings

Joint Industry Council fittings, or JIC, are a type of flare fitting that is machined with a 37° seating surface. JIC connections have wide applications in fuel delivery and fluid power, especially in situations where extremely high-pressure resistance is required, withstanding up to 10,000 psi. One of the most common uses for JIC connections is in the fluid power industry, where they are frequently utilized in diagnostic and test point settings. A three-way JIC coupling can be used to provide a port inline so that any user can connect a diagnostic device or a measurement device, for the purpose of taking pressure readings, as well as to perform system and circuit diagnostics.

British Standard Pipe (BSP)

BSP screw threads have been adopted internationally by virtually all countries other than the United States, which prefers the NPT standard. BSP technical standards relate to the sealing and interconnecting of pipes and connectors which have both an external and internal thread. The pipe-fitting industry and the plumbing industry in all countries where the BSP has been adopted accept it as the standard. The two main types of BSP threads are British Standard Pipe Taper Thread and British Standard Pipe Parallel Thread, and either of these thread types can be combined with one of two joint types, those being longscrew threads and jointing threads.

Japanese Units of Measurement

Professionals within the Japanese islands used to primarily make use of the

traditional Japanese units of measure, which in turn were based on the Chinese system. The Chinese system of measurement spread to the Japanese archipelago and has remained largely intact ever since the year 700. Eventually, Imperial Japan began using the metric system, and at that time all traditional units were defined on the basis of meters and kilograms.

Taiwanese and Korean units of measure are also derived from these traditional measurement units. For a certain amount of time in the 20th century, there were three competing systems of measurement in Japan, being the English system, the Metric system, and the traditional Japanese system. Eventually the metric system was standardized, and all commerce is now conducted using this system, although the traditional measurements are still used in some applications outside of the mainstream.

Split-Flange

Split-flange connectors are generally used in situations where a high degree of resistance to pressure, vibration, and shock is needed. Split-flange connections also help to provide solid connections between a hose and pipe, or between rigid lines. Flange fittings are also highly resistant to loosening and can be quickly and easily assembled. This makes them popular for usage in tight spaces, and since there are at least 700 different kinds of configurations and sizes of split-flange connections, it's usually very easy to find one for any given application.

Have Questions? We Have Answers!

Many of the most popular connectors used in hydraulic systems today have become standardized in this country and others, and the reason for their widespread acceptance generally has to do with their effectiveness at making a tight seal and

preventing leakage. Many of these hydraulic hose fitting connections are also able to tolerate high pressure, and still perform very well without being compromised. For more information about the Hydraulic Hose Fitting that will work best in your situation,

contact us today for more information.

24 hour on-site hydraulic repair, replacement, hose & fitting services.

24 hour on-site hydraulic repair, replacement, hose & fitting services.